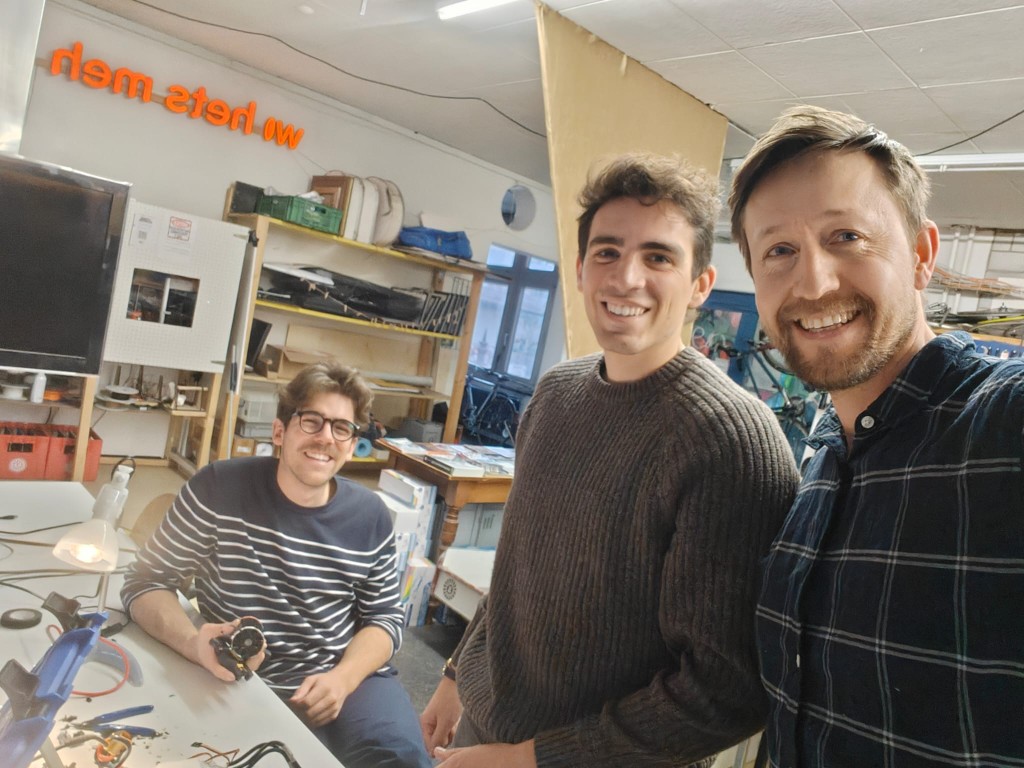

In Action

Vision

Full throttle on a Swiss lake — the E-SUP system powering an inflatable SUP with wireless handheld controllers.

Night ride with integrated LED strips illuminating the water — showcasing the system's auxiliary lighting capabilities.